The call came at 1:47 AM. Always did on Saturdays.

Marcus rolled out of bed, grabbed his toolkit, and drove across town in the dark. Store #447 was flashing red—Low Refrigerant, the panel screamed. Third time this quarter.

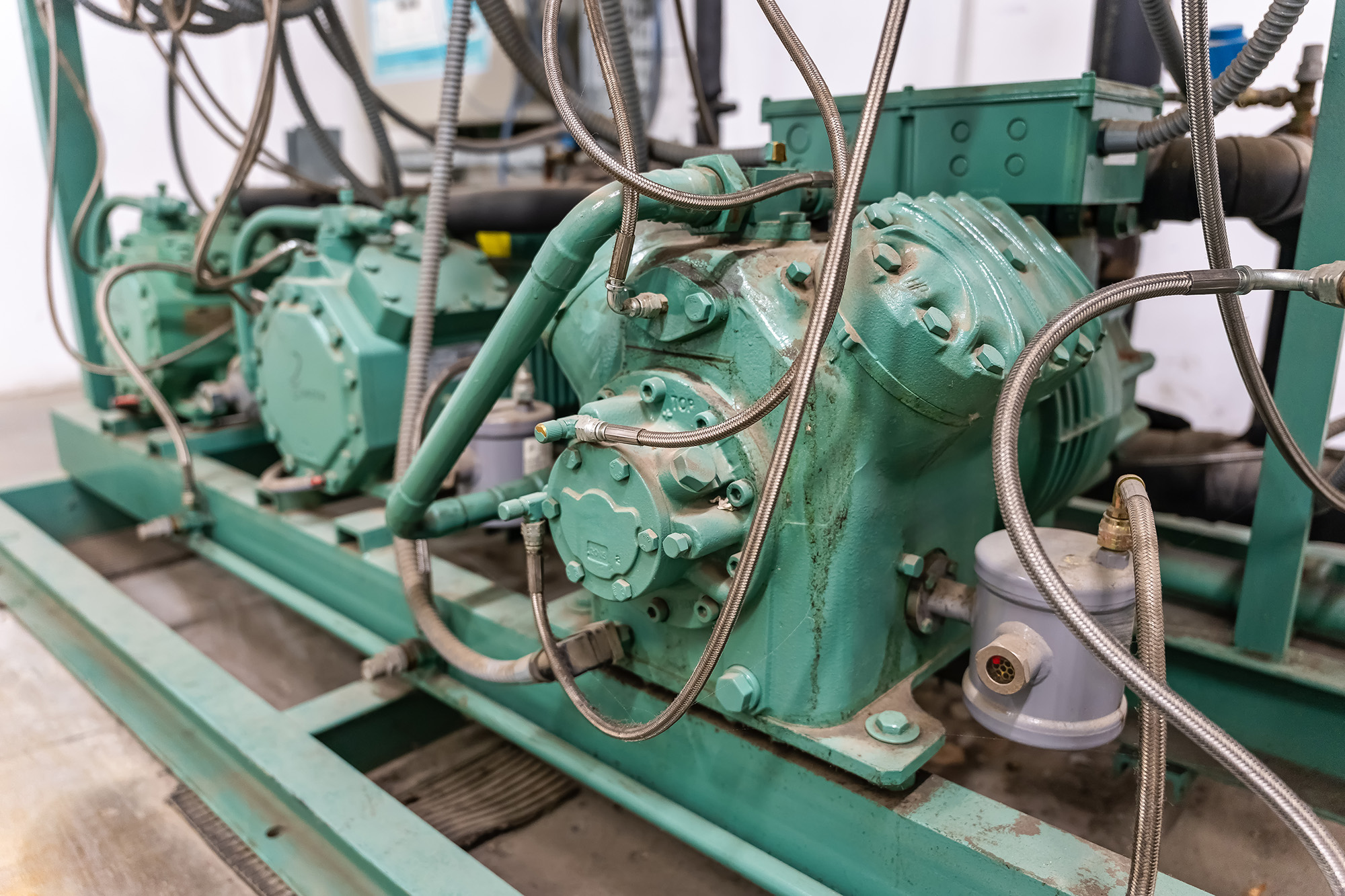

Five minutes in the mechanical room. There it was: a Schrader valve on the liquid line leaking like a guilty conscience, cap nowhere to be found. Classic. Marcus hooked up the gauges, added refrigerant, watched the pressure climb back where it belonged. Saw the receiver level rise. Silence. He twisted a new cap on tight and headed home.

Back in bed by 4:15.

Six hours later, he was on a plane to Florida. Two weeks. Beach. No service calls. The emergency call’s paperwork sat on his passenger seat where he’d forgotten it.

It was 47 days before the grocer received the invoice.

47 days before anyone knew Marcus had pushed the leak rate into exceedance. Above 20%.

The EPA clock had been ticking the whole time. 30 days to repair and inspect. 10 days after repair for verification. Marcus was 17 days over.

The potential fine? $59,117 per day.

The math was simple: $1,004,989.

The day the invoice was received another emergency service call was issued to re-inspect the “repair”.

The leaking Schrader core and missing cap weren’t the real problem. Marcus went back out to perform the follow-up verification only to discover the liquid level in the receiver was perilously low. The alarm just moments from sounding yet again.

He spent two hours tracking down a far more significant leak hidden in the deli case at the metering device.

Repair made. Repair inspected for leaks. Refrigerant added, yet again. When the system stabilized and reached normal operation – follow-up verification performed.

The leak was fixed. The lesson wasn’t. The fine came 2 years later.

A midnight call – Million Dollar cap.